■ Modified plastic

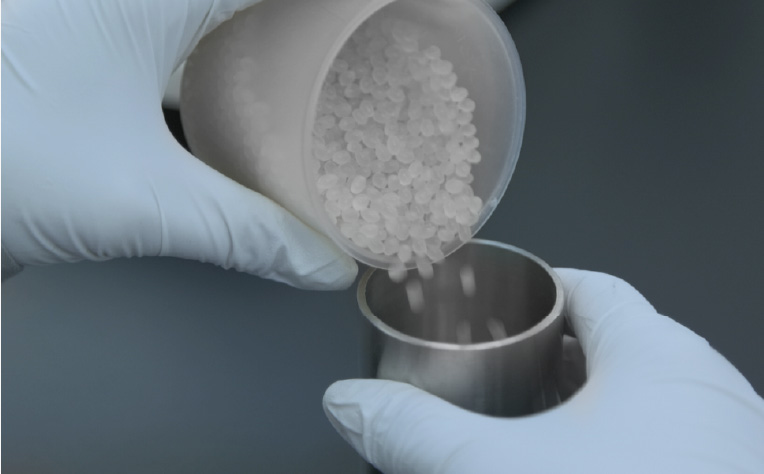

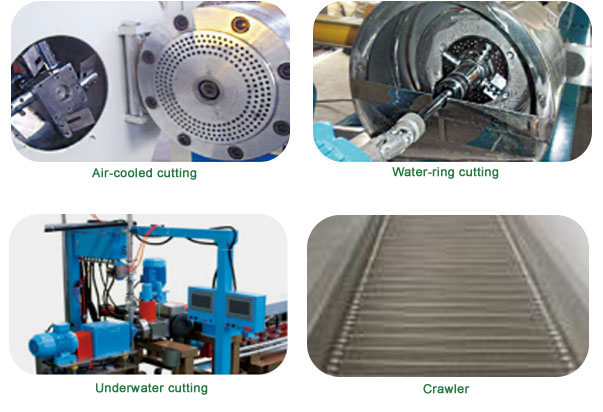

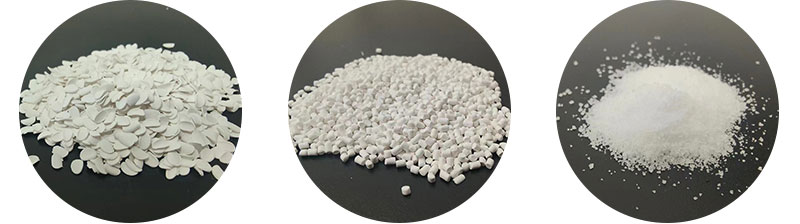

- A plastic modification processing pilot line with Φ35mm high-torque co-rotating double screw; K-Tron loss-in-weight feeder and side feeder can perform preliminary formulation verification for functional masterbatch applications.

- The centers are equipped with special injection molding machines and high-quality molds adhering to the international standard for precision sample preparation, which can be used to prepare various international-standard sample strips, such as ISO and ASTM.

- The centers are also equipped with a variety of advanced testing equipment and instruments, which can be used to conduct comprehensive performance testing and analyze physical, mechanical, thermal, electrical, combustion performance and chemical properties.

■ Direct injection molding

- Demonstration line with accurate 6-bucket weight gain scales, which meets the requirements of traditional production processes where multiple resins + functional masterbatches replace high mixers and/or multiple weighing scales.

-With a screw designed by a BUCT professor, the direct injection molding solution is the optimal choice for products of the same series with different specifications (varied thickness, sizes and colors).

OBP(marine recycled materials) + bio-based fillers (coffee powder, tea powder) masterbatches = green demonstration line for bio-based products.

■ Membrane blowing

- Pilot/production line for fully biodegradable plastics. Small pilot membrane blowing machine (PE, PA dispersion evaluation)

- Cast film pilot line (PC, PET, PP)